Pressure

storm & drainage

wastewater

trenchless/ Jacking

rehab

engineered composites

Pipeline Services

Our manufacturing locations span sea to shining sea.

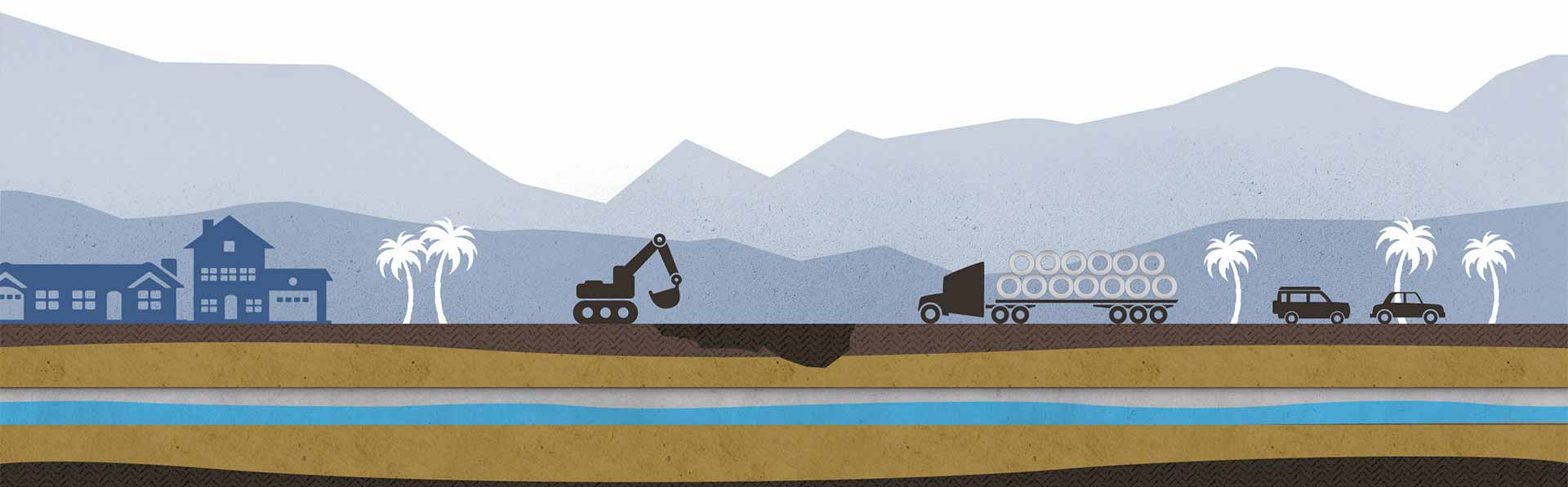

As engineers ourselves, we not only supply but collaborate with you to help you choose exactly the right product for the right application — on a national scale. Thompson Pipe Group offers the largest range of trenchless products and solutions. It’s all backed by the most complete engineering and transportation support in the sector. And a whole lot more.